Products

Contact us

Contact: Mr.liu

Mobile: +86-15141910330

Tel: +86-419-2261766

E_mail:sales@www.yue-da.cn

Current page: Home > ProductsAll automatic horizontal scraper gravity discharge screen centrifuge

Main uses

This product is mainly used in chemical, pharmaceutical and other fields for solid-liquid separation of raw material intermediates and finished products.

Main features

?♦ All closed and clean structure, meets GMP standards and aseptic production requirements on medicines and foods.

?♦ Large flip cover faciliates washing drum and all parts in working area; quick-open type hydraulic lock structure is convenient and reliable for operation.

?♦ Dual shaft sealed structure can ensure that clean areas are not contaminated with lubricants and other contaminants

?♦ Adopts PLC control, touch screen operation, can realize man-machine conversation, convenient for operation and maintenance.

?♦ Actuating element adopts electricity-gas-hydraulic control. Overall process monitoring of on-line cleaning and online sterilization.

?♦ Adopts frequency converting control. Drum speed is stepless adjustable. Technology velocity can be set according to requirements.

?♦ Liquid damping vibration isolation device. No floating platform is required.

?♦ Online cleaning system.

?♦ All automatic online monitoring nitrogen protection system can ensure the centrifue works at positive pressure of inert gases. Online oxygen analyzer can be equipped with to realize anti-explosion requirements if necessary.

?♦ Online sterilization device can be equipped with to perform online sterilization in centrifugal cavity and pipeline.

?♦ Perfect multiple safety protection system, rotate speed monitoring, over vibration protection, open cap protection, overheating and overloading protection, main bearing temperature rise protection, oil cutting-off protection and other devices can ensure the safe operation of the centrifuge.

?♦ Faster filtration rate.

Configuration selection

?♦ Opening assistance: hydraulic, electric, and pneumatic

?♦ Motor drive: common motor, explosion-proof motor and variable frequency motor

?♦ Brake mode: energy consumption and feedback

?♦ On-line cleaning: Shower ball and shower pipe

?♦ Electrical components: Brand supply

?♦ Surface treatment: Mirror polishing, drawing, matting and passivating

?♦ Safety protection: nitrogen protection system, vibration protection, temperature protection, speed monitoring, overload protection and electromechanical interlocking

?♦ Nitrogen protection: automatic nitrogen charging device, oxygen content detection device, liquid seal device and gas-liquid separation device

?♦ Discharge method: slanting type and packing auger delivery

?♦ Vibration reduction: Rubber damping and liquid damping

Materials:

?♦ Stainless steel 304, 321, 316 and 316 L

?♦ Carbon steel or stainless steel coating PE, PP, HALAR (F30), PTFE (F4)

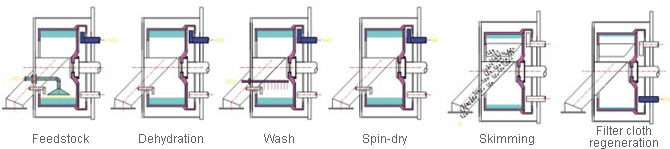

Working process

Bucket-inclined discharge

Auger delivery discharge

.jpg)

Technical parameters

|

Item |

GKH800 |

GKH1000 |

GKH1250 |

GKH1600 |

|

Drum diameter (mm) |

800 |

1000 |

1250 |

1600 |

|

Drum length (mm) |

450 |

500 |

625 |

800 |

|

Working volume of drum (L) |

100 |

165 |

370 |

690 |

|

Maximum loading capacity (kg) |

135 |

225 |

500 |

930 |

|

Drum speed (r/min) |

1550 |

1350 |

1200 |

950 |

|

Maximum separation factor |

1080 |

1020 |

1007 |

808 |

|

Motor power(kW) |

45 |

55 |

90 |

132 |

|

Size (mm) |

2550*1850*1350 |

2400*2150*1700 |

3450*3300*2500 |

4550*2750*2300 |

|

Weight (kg) |

4000 |

8000 |

12000 |

16550 |